Polycarbonate greenhouse diy

Polycarbonate is a polymer plastic, which is formed as a result of the extrusion of polycarbonate granules. It is a high-strength, ductile and resistant to temperature extremes material. Compared to glass, polycarbonate is 200 times stronger. Due to its low weight, it is possible to build different structures from it.

DIY greenhouse greenhouse is the best choice for growing crops in the winter. Another advantage is that, due to the strength and plasticity, snow is kept on the surface of greenhouses, and with an arched structure, on the contrary, snow fall is ensured. Polycarbonate is able to scatter light, which protects plants from sunburn. The main advantage of polycarbonate is to retain heat and distribute it throughout the greenhouse.

You can build a greenhouse with polycarbonate yourself.

The main thing - to choose the right material and know the basic principles of the installation of greenhouses. There are also various polycarbonate greenhouse projects from which you can choose the right one.

Choosing a location

In order to maximize the efficiency of polycarbonate greenhouse construction, it is first necessary to competently approach the choice of location. Greenhouses are located in the north-south direction to provide a greater flow of light. To reduce the influence of northern winds, it is better to install closer to the buildings.

It is better to deepen the greenhouse by 70 cm, which will save on fuel and reduce the number of temperature fluctuations. Sources of electricity and water should be located near the greenhouse.

When the place for the greenhouse is determined, it is necessary to think over the form of the structure, its dimensions, draw a drawing of the greenhouse from polycarbonate, design the foundation and frame, conduct heating and additional lighting.

How to make a drawing

Drawing for polycarbonate greenhouses, installation of which is done by hand, is much easier to make than it seems at first glance. Before proceeding with the design of the drawing, you need to determine the shape of the structure, as well as the materials used.

The following basic forms of greenhouses and greenhouses exist:

- rectangular;

- arched (the most popular greenhouse bread);

- in the form of a house with a sloping roof.

For rectangular-shaped greenhouses or with a sloping roof, polycarbonate sheets 4–10 mm thick are best. The best option is sheets with a thickness of 6 mm, for arch-type structures - 4 mm.

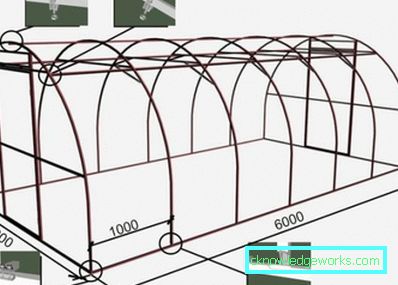

After the selection of materials, a greenhouse scheme is made. First of all, the dimensions of the structure are determined, taking into account the minimum width of 2.5 m. Greenhouses with an area of 50 square meters m used for growing crops for commercial purposes.

If you take into account the parameters of polycarbonate sheets and design the dimensions of the walls based on this, you can save money on purchase and reduce the amount of waste.

In the drawing, greenhouses also reflect doors and air vents for ventilation.

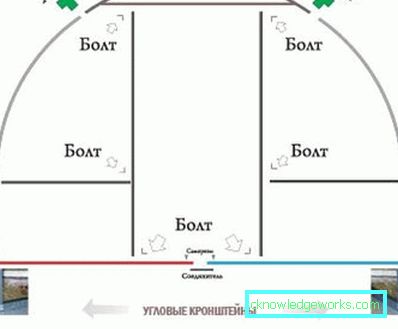

Polycarbonate Greenhouse Drawings

Making the foundation

Before laying the foundation, you should prepare a place for construction: level the area if necessary, clean up the garbage. The best, strong and durable is a monolithic foundation of reinforced concrete. To do this, dig the desired size of the trench, it poured concrete. Reinforced concrete foundation is the most expensive, so it is better to resort to it for the construction of winter greenhouses.

A cheaper option is the creation of a column base. Support pillars with a length of about 3 m are installed in dug pits with a depth of about 50 cm. Thus, the 50 cm post goes into the ground, and the remaining 2.5 m serve as a support for the walls. After installing the columns, they are poured with concrete, waiting for complete drying (usually several days) to avoid the formation of cracks.

What to make frame

The material for the frame of the greenhouse can be:

- wood,

- metal or galvanized profile.

The simplest and most economical option is to install a timber frame. For this, oak or larch bars are used. Before construction, the bars are treated with special antifungal agents.

Despite the fact that the installation of a wooden frame is not so difficult, its obvious drawbacks are the fragility and poor conductivity of heat.

For large greenhouses, it is better to choose a metal profile. It is stronger, but requires considerable effort to install. Before installation, the profile is processed with special anti-corrosion agents.

The framework from a galvanized profile is suitable for greenhouses, small by the size. It bends well, light and protected from corrosion.

Mounting sheets

After the installation of the frame go to the installation of polycarbonate sheets. But before that, first the packaging film is removed from the sheets, edges are processed with glue, plastic corners are installed. The bottom edge of the sheet is sealed with a perforated mounting tape, and the top edge with a mounting tape or tape.

Polycarbonate sheets set vertically in the direction of the slope of the roof. For fasteners use screws and heat washers. Strips of iron or corners of the arches can serve as pressure plates.

Holes for mounting polycarbonate to the base of the frame should be drilled 2 mm more. And the holes intended for fastening the sheet to the foundation should be 2 times the diameter of the screw. These nuances of mounting polycarbonate sheets associated with the property of polycarbonate to expand. When drilling holes in sheets, it is necessary to exclude the ingress of dust and water, otherwise the destruction of polycarbonate may occur later.

During the construction of arched greenhouses, sheets are laid across the frame. Bending radius is 2 m.

First of all, the sheets are mounted on the roof, then the ends of the arches, walls, doors and vents are installed. Connecting strips sheets fasten. The corners between the sheets are covered with plastic or metal corners. Complete installation of sheets with light-reflecting treatment to improve lighting.

Greenhouse from polycarbonate do it yourself (video)

How to make lighting and heating

The fundamental point in the installation of a greenhouse is lighting and heating. To provide additional lighting is better to use energy-saving light bulbs.

Heating in the greenhouse can be provided in several ways:

It is important not to forget about the ventilation of the greenhouse, for this the greenhouse project must assume the presence of windows and doors.

Winter greenhouse

If it is intended to use a polycarbonate greenhouse not only in the summer period, then it is possible to build a more reliable and durable construction. In this case, the place for the winter greenhouse is better to choose as close as possible to the house or create it at the top of some buildings. To save on fuel for heating a greenhouse, it can be slightly deepened when building into the ground.

Cellular polycarbonate with a thickness of 1 cm is best suited for installation. The height of the greenhouse should be optimal - 2.5-3 m. Gaps and cracks are not allowed in the fasteners of a winter greenhouse. The foundation is better made of concrete. Any type of heating used in the construction of conventional greenhouses will be suitable for heating a winter greenhouse.

Gallery: DIY greenhouse greenhouse (25 photos)