Cold welding abro steel (18 photos)

Abro Steel Cold Welding: Composition, Properties and Applications

Often in life you have to deal with emergencies in the form of pipe leaks, holes in the radiator and gas tank, etc. To quickly fix such a nuisance, it is recommended to use the adhesive mixture (cold welding) Abro Steel. She is well known in the construction market and has received positive feedback from numerous buyers, as it provides a reliable and high-quality connection.

Features

Cold welding is a unique adhesive material, which includes steel powder and epoxy putty. These components are thoroughly mixed in the production process, after which they enter into chemical reactions with the hardener, forming a universal mass that is resistant to high temperatures and corrosive media. Despite the fact that the material contains a metal filler, in the frozen state it is absolutely neutral to alkalis, acids, water and poorly conducts electricity.

Cold welding begins to show its performance, a few minutes after it is mixed and applied to damaged parts. Homogeneous mass is ready for use immediately, it fills all hollow areas and cracks, after which it gradually reaches strength and after one hour finally hardens.

Then the surface treated with the mixture can be machined, taking into account the following features:

- joints covered with adhesive mass are unstable to shock deformations;

- cold welding dries quickly, and within an hour after its application it will withstand such effects as tension and compression;

- The parts glued together with the composition may have a slight resistance during bending and torsion;

- frozen mixture is not deformed when compressed.

Work on the application of cold welding should be performed under normal temperature conditions, since its reduction or increase can slow down the hardening process. In addition, it is strictly forbidden to add other components to the glue, accelerating the hardening. Increased hardener concentration will affect the physical properties of the material, and it will lose its original characteristics.

The adhesive composition is usually white in color, but black welding is also found on the market, which is designed to repair breakouts and through holes.

Abro Steel high temperature cold welding has several advantages:

- allows you to create high-quality compounds that are resistant to heavy loads;

- used for bonding any solid elements;

- suitable for working in adverse conditions;

- strength and durability;

- convenient packaging and ease of use.

As for the shortcomings, they are not. If the mixture is stored and complied with all the rules of operation, the components will not lose their performance and ensure reliable fastening of parts.

Scope of application

Abro Steel is a universal adhesive that is ideal for bonding homogeneous elements from non-ferrous, ferrous metals, wood, glass, ceramics and plastic. As a rule, it is used in the repair of automotive, swimming equipment, to eliminate gusts and cracks in pipelines. In addition, the adhesive mixture is indispensable in the repair of furniture and the restoration of coatings made of concrete or stone.

With the help of this material, it is possible not only to eliminate breakdowns in the autoradiator and the engine of the car, but also to make reliable sealing of the body, metal parts and batteries. During the repair of swimming facilities, the hull of the vessel is treated with an adhesive, and the setting elements and instrument parts are attached. Cold welding is also in great demand in everyday life; it is acquired for the repair of bathtubs, basins, toilet bowls and decorative finishes. In addition, if there was a pipeline breakthrough in the apartment, then emergency repairs are indispensable. In this case, the masters use an adhesive mixture and restore the water supply system, applying a mass to the damaged joints.

We can say that cold welding of the Abro Steel trademark is considered to be a multifunctional product, which is characterized by high quality and helps to instantly eliminate emergency situations in any conditions.

How to use?

Before applying the adhesive composition (for example, AS 224), it is necessary to carefully prepare the working surface, which is to be restored, this will provide a strong and high-quality bonding. Damaged areas must be degreased and cleaned from chemical contamination and paint. In the case of emergency fixes and plugging gaps, you can do without preliminary measures, but in such situations the quality of the connections will be lower.

This also applies to the repair of tanks filled with liquid, when the mixture is applied under the surface of the water. Due to the inert properties of the material, they can seal aquariums, boilers, yachts and boats without first preparing the damaged areas, creating a strong mount in the water.

After the surface is cleaned and ground, a simple instruction is applied.

- The required amount of welding is cut off. This should be done perpendicularly, then it is necessary to moisten hands with water and mix the composition well until a homogeneous mass is obtained. The mixture will heat up a little during mixing, so you should not be afraid.

- Mix is applied on the basis and give it the necessary form. If the repair is carried out under water, then it should simply press to the surface and wait until it locks.

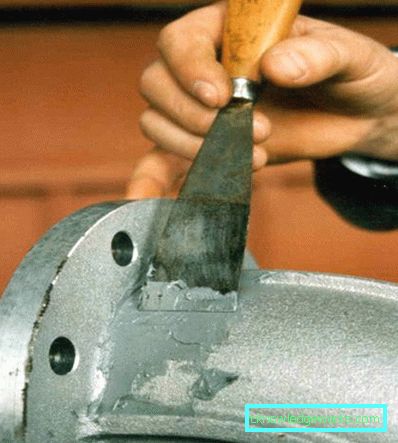

Similar actions can be performed to restore the threaded joints, as cold filler contains steel fillers. In this case, a layer of the mixture is applied to the damaged place and after its complete solidification, mechanical processing is carried out to obtain a cylindrical surface. Then, using special equipment, threading is performed.

See the Abro Steel cold welding overview below.